Resistance heating

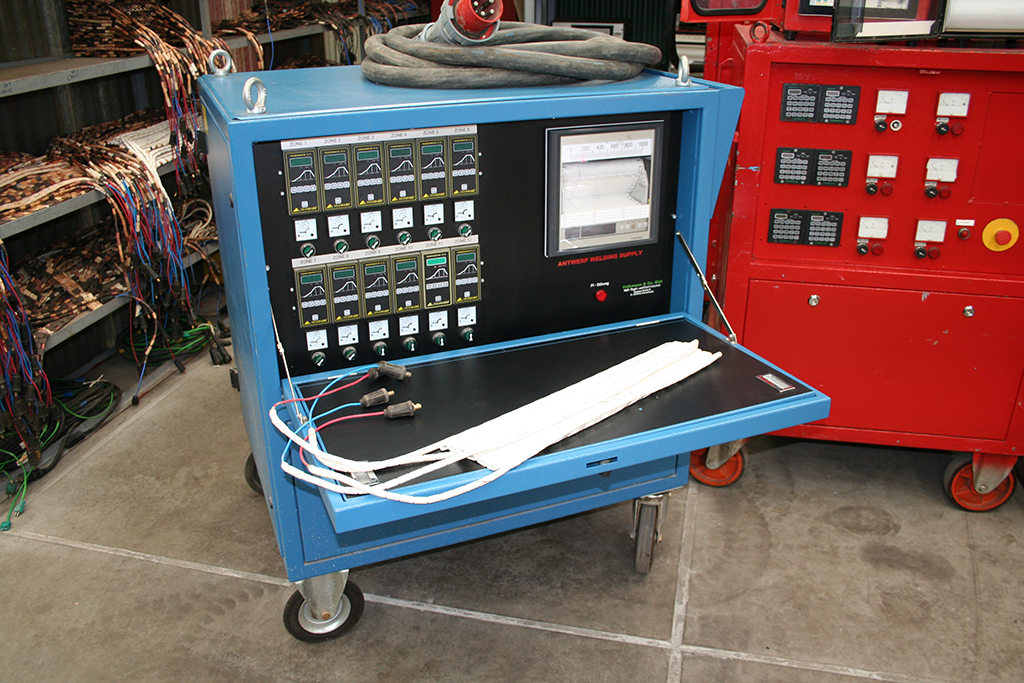

Antwerp Welding Supply nv has an extensive range of resistance heating devices with different capacities. The heat treatment with resistance heating has the advantage that it can be carried out on site.

Antwerp Welding Supply can assist you with different types of heat treatments for your workpieces, using resistance heating. These services consist of preheating, soft annealing, normal annealing / normalizing, tempering, refining or hardening.

Most annealing techniques are mainly applied after other machining processes, such as welding or forming of metal, to improve the mechanical properties of the material. Preheating, on the other hand, is performed before processing the metal.

Resistance heating

Annealing techniques with resistance heating

We also have an extensive package of resistance mats to provide the workpiece with the necessary heating elements.

The advantages of our resistance heating:

- Flexible and mobile

- Compact machines with high power

- Registration of the heat profile with a recorder

Heat treatments

Heat treatments with resistance heating

Preheating

Preheating of metal is applied to minimize the stresses that arise during welding.

This technique reduces the temperature difference between the processed material and the welding work, so that the thermal stresses around the weld are reduced to a minimum.

Soft annealing

Soft annealing is a technique to improve the processing and deformation of metal. The metal is, as it were, made softer by this treatment.

Soft annealing has a negative impact on the tensile strength and hardness of the metal, but the flexibility of the metal increases and therefore makes it easier to work with.

Normal annealing

Normal annealing or normalizing ensures that the metal is returned to its original state as much as possible. All operations such as welding, grinding, etc. weaken the metal.

Thanks to this heat treatment, the material regains a finer structure, which improves the tensile strength and hardness of the workpiece. The tensions in the material that were caused by the processing are minimized again in this way.

Low stress annealing

This annealing technique is mainly applied to metals that have been worked or deformed in the cold state, such as folding or rolling the metal.

A heat treatment of the materials for 2 hours greatly reduces the internal stresses in the material caused by the cold working.

Hardening

The purpose of hardening steel is to strengthen the material and make it more wear-resistant.

With this treatment, the steel is heated to above 800°C and then cooled quickly by means of water or oil. However, this does increase the brittleness of the metal and any subsequent tempering treatment may be advised.

Tempering

Annealing or tempering of steel is usually performed after hardening the steel.

Annealing steel at lower temperatures around 200°C reduces the brittleness of steel, without hardly having an impact on the hardness and tensile strength of the metal.

Refining

The refining of steel involves 2 processes, namely hardening and tempering, but at a high temperature.

Both strength and toughness of the metal are favorably influenced by the refining process. In order to guarantee the tensile strength and toughness of the material, a high temperature is used during the tempering.